Jay joined Madsen Giersing in October 2020 and brings over 30 years of experience in maritime infrastructure engineering to the organisation. Across his career, Jay has supported the delivery of major projects across Australia and the Middle East, including Townsville Port Inner Harbour Expansion, Port of Brisbane Wharves 11 and 12 and Kingsford Smith Drive Upgrade Project.

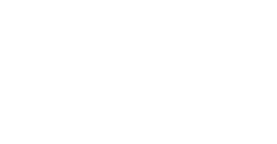

We caught up with Jay to find out more about his career, the Firth of Forth Bridge and his admiration for Isambard Kingdom Brunel.

Why did you become an engineer?

My school friend’s father was an engineer, and he intended to become an engineer. This brought engineering to my attention, and I realised that I enjoyed the problem solving that engineering involves, and my best abilities at school appeared to be suited for engineering.

What do you love about engineering?

Being able to formulate economical and constructible designs that best meet the client’s often competing design requirements, the sheer variability of the work and structures that I am involved with and seeing my designs go from paper (computer screens these days) to reality.

What are you working on at the moment?

There is a new community/ferry jetty near Cairns and a buried corrugated steel arch bridge structure for a mining heavy vehicle haul road river crossing in the Northern Territory.

What has been your greatest professional achievement to date?

Professional achievements that stand out for me are:

- Being onsite to see the construction of my first major design project, a large steel-framed cold store in western Sydney.

- Formulating the winning tender design for the Kingsford Smith Drive upgrade riverbank structure in the two-day window available after the client finally decided which option to proceed with.

What’s the best project you have worked on?

The container wharf mooring bollard upgrade for the Port of Brisbane required very bespoke solutions. The critical requirement of minimising disruptions to the wharf operations resulted in very tight windows to replace individual bollards on the wharves. The solutions adopted to achieve this included:

- Custom designed mooring bollards,

- Precast concrete blocks to raise bollards up from recesses to deck level and allow the existing wharf structures to accommodate the higher bollard loads (every block was unique); and,

- Increasing the lateral load capacity of a short wharf segment by structurally connecting it to an adjacent wharf segment by tying these together with post-tensioned stress bars placed in recesses cut into the deck slabs.

The project was successfully completed with minimum disruptions to the wharf operations.

What’s the most useful thing you’ve learned throughout your career?

Always ensure that all of the design requirements/parameters/assumptions are fully documented/stated/agreed, even if these would normally be considered to be obvious before the design commences.

What would your last meal be?

Apricot chicken & rice.

What is the last movie you watched or series you binged?

The last series binged was Resident Alien, starring Alan Tudyk as a crash-landed alien named Harry. He takes on the identity of a small-town Colorado doctor and slowly begins to wrestle with the moral dilemma of his secret mission on Earth.

Who’s the greatest engineer of all time and why?

Isambard Kingdom Brunel due to the wide range of different innovative and groundbreaking structures he designed and projects he managed, and the effect he had on the engineering profession.

What excites you about the future of our industry?

The engineering profession will be critical in developing and realising soutions to the large problems that are emerging, from water security and transport, to energy generation and storage. Engineering will be critical to how we meet those challenges and adapt our infrastructure solutions.

What would be your dream project to work on from history?

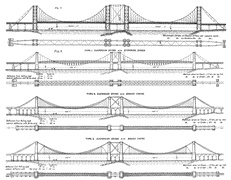

The Firth of Forth Bridge.

The Forth Bridge is a cantilever railway bridge across the Firth of Forth in the east of Scotland, 14 kilometres west of central Edinburgh. Completed in 1890, it is a UNESCO World Heritage Site, and when it opened, it had the longest single cantilever bridge span in the world. It continues to be the world’s second-longest single cantilever span, with a span of 1,709 feet (521 m) and was a massive feat of design, engineering and construction.

What piece of advice would you give to an aspiring engineer?

Always consider the constructability of a design as the lightest and thinnest design on paper may not be the most constructible and economical design.

Be thorough with all elements of the design as it is the smaller elements of the design that may not be considered as important that are most likely to cause problems/issues.